The coronavirus pandemic has caused once-in-a-lifetime disruption to the way people live and work around the world. Virus-related challenges can be found in virtually every industry, and businesses are struggling to find ways to survive this uncertain time. One of the sectors that have been greatly affected by the pandemic is cold chain logistics. Demand for fresh food and vaccines has skyrocketed and will continue to grow as cities and states enforce stay-at-home orders. As the need for greater cold chain monitoring increases, the adoption of LoRaWAN technology will play a big role. In this article, we’ll focus on how to achieve cold chain monitoring with LoRaWAN technology.

What is meant by cold chain monitoring

Cold chain monitoring generally refers to the process of utilizing Internet of Things (IoT) technology to continuously monitor and record the temperature of temperature-sensitive products. It helps a lot to facilitate the optimal delivery of pharmaceuticals, perishables, biologics, food and beverage while ensuring their freshness and effectiveness in a temperature-controlled supply chain. Without proper monitoring of the shipping and storage environment, the effectiveness of the products may be reduced or even damaged.

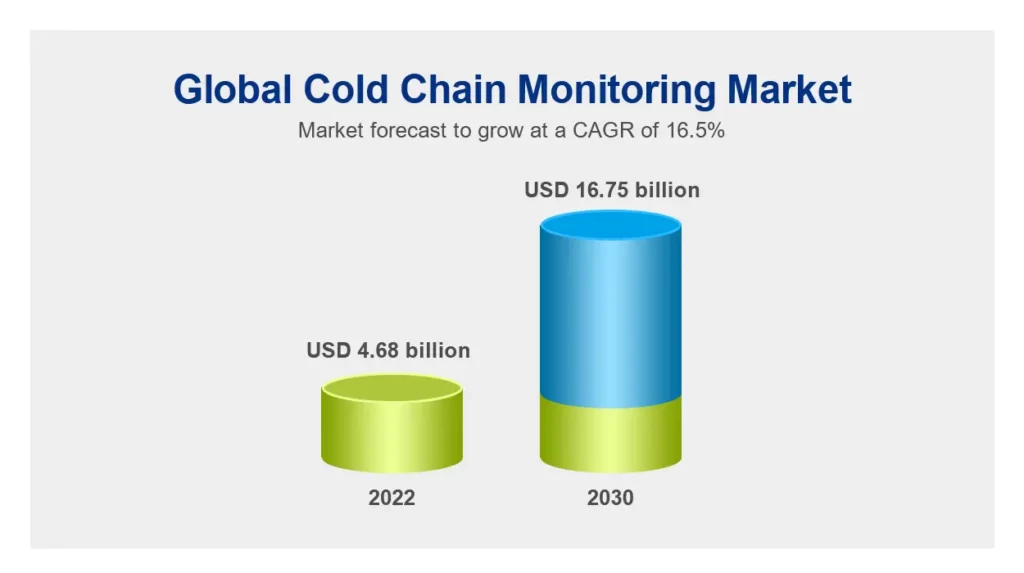

The growing awareness of cold chain product preservation and IoT technology have contributed to the improvement of cold chain monitoring. The global cold chain monitoring market is valued at USD 4.68 billion in 2022 and is projected to reach USD 16.75 billion by 2030. There are many factors that impact the quality of cold chain products in transit, such as temperature, light exposure, and humidity. Efficient cold chain monitoring and management is critical to control these variables and ensure that products are maintained within defined temperature ranges.

Challenges encountered by cold chain monitoring solution

Cold chain monitoring is not as easy as it seems. Logistics companies dealing with temperature-sensitive products may encounter various obstacles in ensuring the damage-free transport and storage of their products. As with any industry, there are difficulties that, if not addressed, could have significant security and financial ramifications. Below are some of the pain points faced by cold chain monitoring.

Manual data reading. Most of the refrigerated warehouse and transport vehicles still applies traditional cold chain monitoring tools, which only display the current temperature and humidity values locally. And special personnel are required to regularly and manually register the temperature and humidity values.

No history data archiving. Some of the cold chain monitoring devices come with no internal data storage function, so history data cannot be queried except the transcribed temperature and humidity values that manually entered into the system. Data import is difficult, inefficient, and costly.

Poor timeliness of temperature monitoring. There is no wireless connection between the cold chain monitoring tools and database, so it’s impossible to update the real-time temperature and humidity values on application server. And abnormalities cannot be detected and resolved in time.

Difficulty in data traceability and supervision. Due to the fact that the data cannot be imported into the central database in real-time and completely, there is great difficulty in data communication, historical data query, resulting in poor operability of an connected cold chain monitoring solution.

How to monitor a cold chain with LoRaWAN

Cold chain monitoring is essential, whether in a storage environment or in transit. To ensure uninterrupted maintenance of the cold chain, it is necessary to develop a cold chain monitoring system that is as comprehensive, automated, and error-free as possible, while guaranteeing that the desired temperature range is always met. Due to its wide coverage, low power consumption, and high scalability, LoRaWAN technology is gaining popularity in cold chain monitoring applications.

A LoRaWAN-enabled cold chain monitoring system typically consist of a set of LoRaWAN sensors, LoRaWAN gateways, cloud server, and application. The best chain monitoring devices such as LoRaWAN Temperature & Humidity sensor and LoRaWAN tracker can be placed inside storage warehouses, refrigerated trucks, and distribution centers. The LoRaWAN gateway collects the environment information from the cold chain temperature monitoring devices, and transmit the data to the cloud for processing. Then businesses are enabled to have complete control over cold chain temperature and location tracking.

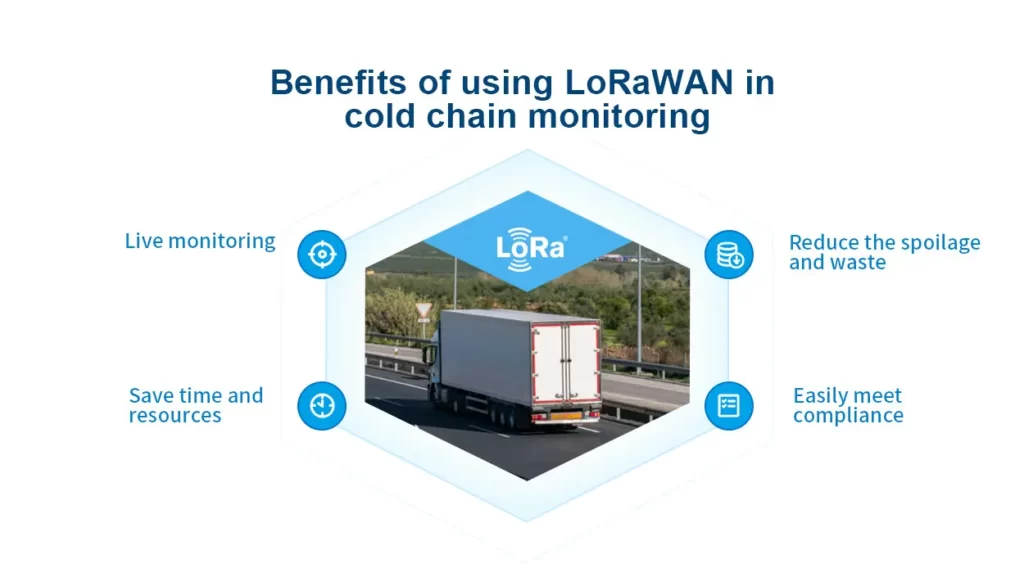

Benefits of using LoRaWAN in cold chain monitoring

There is no surprise that the benefits of leveraging LoRaWAN technology in cold chain monitoring are numerous. The new wireless technology helps overcome various challenges encountered by cold chain monitoring and allows businesses monitor their temperature-controlled supply chain efficiently. The high level of control and information provided by LoRaWAN makes it a valuable candidate for addressing major supply chain issues for years to come. Let’s look at the main benefits of using LoRaWAN in smart cold chain monitoring.

Live monitoring

The adoption of LoRaWAN technology promises an increased visibility and control for the smart temperature-controlled supply chain. By employing a variety of smart sensors at different stages, stakeholders can have a real-time tracking and monitoring picture of the storage environment of the products as it moves from one point to another. If there is any temperature excursion, real-time alerts will be notified for faster action and loss avoidance. Moreover, actionable insights can be generated to modify the temperature of the cold storage facilities to meet the desired level.

Reduce the spoilage and waste

A significant amount of food and medicine waste is caused by inefficient handling and storage every year. With smart sensors continually measuring the temperature and humidity of perishable items, safe transit and storage condition can be maintained to ensure the quality and effectiveness of commodities. Real-time temperature monitoring plays an important role in determining whether the ambient temperature of the products exceeds the standard, thereby reducing unnecessary losses caused by spoilage and damage.

Save time and resources

One of the key benefits of implementing LoRaWAN in cold chain monitoring is the ability to save time and resources in supply chain. Without a cold chain monitoring system, it can be difficult to know where your products are and how they are kept at any given time, leading to cold chain breaks. The LoRaWAN-enabled cold chain monitoring solution helps automatically track and update the location and condition of your products. This means that you don’t have to manually check the required information, which can save a lot of time and resources.

Easily meet compliance

A cold chain monitoring system is a big help when it comes to meeting compliance. Temperature is a significant metric regarding of food and drug safety. According to HACCP, in addition to the inspection of food shelf life, outer packaging and food appearance, food safety management must also conduct strict and continuous inspections of the internal temperature of food during storage and transportation. With regard to the cold chain of drugs and vaccines, there are higher requirements for their storage and transportation environment.

What to consider when selecting a cold chain monitoring

The increased need for greater monitoring and visibility of frozen foods, dairy products and pharmaceuticals, as well as stringent regulations related to storage and transportation, will drive the need for cold chain monitoring solutions. Due to the fact that not all IoT cold chain monitoring solutions are created equal, there are some factors that you should take into account when choosing an IoT cold chain monitoring solution.

Consider the cost of the solution. Budget always comes first when choosing an available cold chain monitoring solution. It’s important to choose the solution that fits your budget.

Define what data needs to be collected and how accurate the data is. Make sure what data is necessary to collect, such as temperature, humidity, light, shock, location, etc. Some cold chain solutions provide detailed real-time information, while others only provide basic data updated hourly.

Find out the most beneficial functionality. Look at the features and functionality of the various cold chain monitoring solutions in the market, and decide what is the most important for your business. Often, extra features always come with an additional cost.

Look at scalability and ease of use. Some cold chain monitoring solutions are user-friendly and easy to implement, while others are more difficult to adopt. Make sure the solution you choose is easy to use and scale.

Determine single-use vs reusable. Make sure you choose a reusable cold chain monitoring solution rather than a single-use one. Reusable cold chain monitoring devices will drive a high return on investment. It’s expected to see substantial savings over time.

Achieve real-time cold chain monitoring with MOKOLoRa

Cold chain monitoring is critical in preserving and shipping refrigerated items, especially during the COVID-19 pandemic. As the Internet of Things continues to evolve, LoRaWAN wireless technology has emerged in a competitive market with its long range coverage and low power consumption. The adoption of LoRaWAN is valuable in cold chain monitoring that incorporates automated and digital solutions. If you are searching for reliable temperature monitoring devices and LoRa GPS tracker, MOKOLoRa can be your best partner.